Conversely, a plasma cutter presents comparatively decrease accuracy than the usual laser cutter but is best suited for cutting thicker metals, which usually is often tricky to machine with a laser cutter.

CNC Milling Machines: CNC milling machines use rotating cutting tools to get rid of material from workpieces. They are versatile machines frequently used when generating complex parts with intricate details.

Following, CAM system software generates the instructions for tool motion dependant on the CAD design, referred to as G&M codes. This method is also referred to as CNC programming; the codes are readable by CNC precision machines.

Backstage modifying Throughout This system processing, other unique programs is usually edited,totally applying of system resources,rational arranging of your time,and bettering the efficiency of Procedure of the machine.

In this manner, milling machines rotate, interlock and grind factors – system steps for which independent machines are used in the normal way. The result of producing in only one fixture is that the element excellent boosts significantly and throughput instances are dramatically decreased.

CNC Grinders are put up-processing equipment used in high-precision producing. They contain a rotating grinding wheel with an abrasive layer of certain thickness and grain size. The machined parts are fed into the wheel to eliminate surface imperfections and clean the floor by cutting the slight resources and irregularities with the abrasive.

CNC routers are characterised by their ability to use Laptop numerical control to route spindle and machine tool paths to design and shape materials like Wooden, steel, composites, aluminum, foam, and plastic, into the specified design and shape.

Integration: It uses software integration to produce highly comprehensive and complex parts rapidly and efficiently. Utilizing CAD/CAM software enables designers and producers to streamline the production procedures extra efficiently though developing complex parts quickly.

Through vertical milling, the milling tool is guided from previously mentioned onto a workpiece to get machined. The vertical development is usually a very common design of milling machines, mainly because it offers a Obviously seen working place.

For typical machining, versatility and adaptability are essential to dealing with an array of tasks. The GTX gang tool lathe from Cubic Machinery offers the flexibleness required for numerous machining applications, with its Y-axis sliding headstock and optional live tools. The machine’s C-axis control allows for simultaneous X, Z, and C-axis actions, improving the opportunity to machine complex parts with several functions.

In today's competitive landscape, are you currently self-confident your production procedures can satisfy the requires of 2025 and over and above? The need for enhanced precision, efficiency, and adaptability is OKUMA LB2000 EXII MC simple. Advanced CNC machining offers a strategic gain, enabling producers to overcome difficulties and unlock new alternatives.

five-axis milling permits Just about any wanted movement on the workpiece or the milling head, enabling even complex geometries being attained in a single clamping.

It is the non-Make contact with machining method that erodes the fabric by producing An electrical spark (discharge) to build the cuts. Listed here, the workpiece and tool work as electrodes and generate discharge as a result of die-electric powered fluid by which they are immersed.

Listed here, we’ve collected some essential details and vital concerns to help you accomplish the desired final results.

Hallie Eisenberg Then & Now!

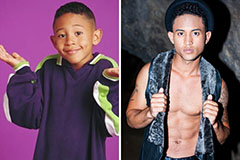

Hallie Eisenberg Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!